Next year will see the world’s first zero emissions, fully autonomous container ship embark on her maiden voyage between three towns in Southern Norway. This move will revolutionize the Perth sea container transport industry in the future as these vessels are expected to be a cost-effective measure in operating costs and also will also reduce fuel emissions both from the vehicle itself being electric and decrease heavy truck journeys by 40,000 each year. It will also improve road safety and encourage companies to consider sea transportation for their goods, once the positive effects are seen.

First in the World

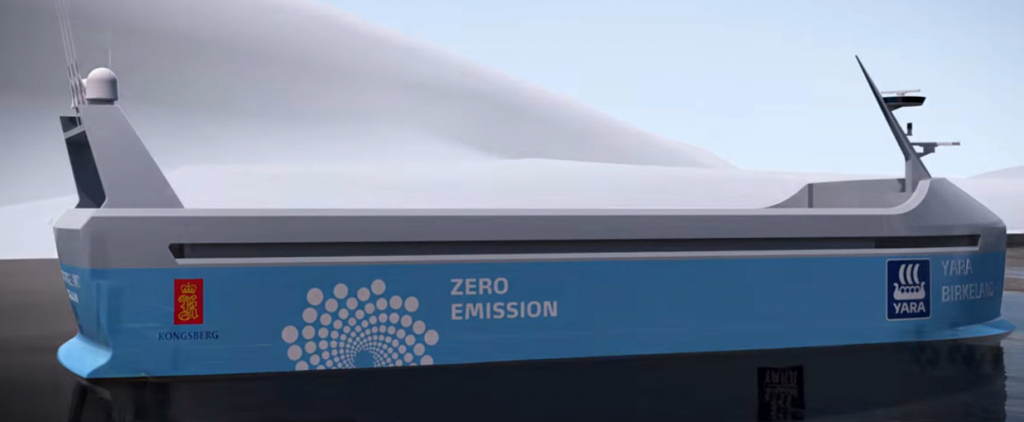

The vessel, named Yara Birkeland, is under development by chemical manufacturers Yara in partnership with aerospace company, Kongsberg. Building the ship will cost approximately $25 million, which is almost three times the cost of a similar sized container ship, but it is predicted to save in the long term as it will eventually operate completely without a crew and won’t require traditional fuel.

Safety

The vessel is expected to be a safer option than normally manned sea container ships. It may come as a surprise to most people, who hear more about airplane crashes, that you are much safer in the air than at sea. Thousands of people die at sea every year and it’s often a case of human error. Whilst there are International Regulations for the Prevention of Collision at Sea defined by the International Maritime Organisation and governing all international waters, sailors must be of clear mind to act appropriately, and this is not often the case at sea.

Those working onboard can often work long hours or at least be away for long periods at sea and don’t get adequate rest, affecting their reaction speeds and critical thinking skills. Although each seafaring person knows the ‘COLREGS’ (the regulations mentioned above), whether they have a yacht in Fremantle or are a working fishing vessel operating in open water daily, it is difficult to spot situations and react accordingly if you are suffering burnout onboard a merchant vessel at sea for weeks on end. Change the scenario to a robot concisely interpreting the ‘COLREGS’ and implementing them and it seems highly likely that the world’s sea lanes will become safer with this development.

Merchant vessel accidents have made the news on a number of occasions this year, the most tragic being the collision of a US Navy Destroyer into the Alnic MC. The two vessels collided in one of the world’s busiest shipping lanes, the Malacca Strait, and seven sailors died. The Navy crew onboard were criticized for their lack of situational awareness in not preventing the collision. Incidents such as these serve as a reminder that human error costs lives at sea and when the Yara Birkeland is fully unmanned, it and the other vessels that follow in its path will not be subject to these fatal mistakes.

Maiden Voyage

Yara currently produce fertilizer in the city of Porsgrunn and transport it to the ports of Brevik and Larvik by road, for distribution around the world. This is a costly affair that requires over 100 truck journeys daily, emitting a large amount of carbon into the atmosphere.

The Yara Birkeland will take the containers from Heroya and travel down the Norwegian fjords to Brevik and 30 nautical miles further to Larvik. This primary route will save hundreds of tonnes of CO2 emissions each year.

The maiden voyage will have a crew to monitor the decision-making process and ensure that the programming contains no errors. From 2019, the ship will sail without a team of sailors but a shore team will be on 24-hour watch to observe the sensors and make sure that it is does not run aground. These voyages will serve as transformative for the industry as others watch how the Yara Birkeland navigates around the waters of Norway without a human onboard.

2020 will see the Yara Birkeland set off solo and begin to fully display its’ cost and energy saving capabilities. It will also travel within the Norwegian Coastal Administration Vessel Tracking System area, which is essentially an air traffic control for shipping.

Sensors

Kongsberg have developed a broad range of sensors for the feeder containership. These sensors will inform the ship of its current location, planned route, how to navigate it along with what other vessels are in the vicinity. Other internal sensors will monitor the equipment onboard, which has been strategically placed for the best outcomes. Radar, cameras and infrared cameras will all be installed on different parts of the vessel, which will be monitored in the early voyages to see that the ship is making the correct ‘decisions’.

With all this new technology, it is likely that the Yara Birkeland will have the capability to see far more than an officer on watch does today. Another advantage is that its’ systems can ‘see’ in many directions and from many perspectives at once, something that simply isn’t possible by humans. One of these perspectives is from low on the bow, which has presented a challenge to sailors in the past.

No Crew

As more autonomous vessels take to the waters in the path of the Yara Birkeland, shipping companies will experience a huge reduction in costs of keeping a crew onboard. Heating and fresh water systems will no longer be required, there will be no space for crew accommodation and no food will need to be brought onboard. This all impacts the use of diesel, resulting in cost savings and better environmental practice. Salaries will also represent another huge reduction in company costs.

With over 90 per cent of the world’s trade carried by sea, and the Yara Birkeland set to transform the industry, it is safe to say that shipping is about to become a lot more cost effective over the next 20 years.

Gecko Logistics are at the forefront of transport companies in WA and can offer a range of options for container shipping. Call us on 1300 744 192 or email bookings@gecko.onpressidium.com to speak to us about your logistical needs.